Products

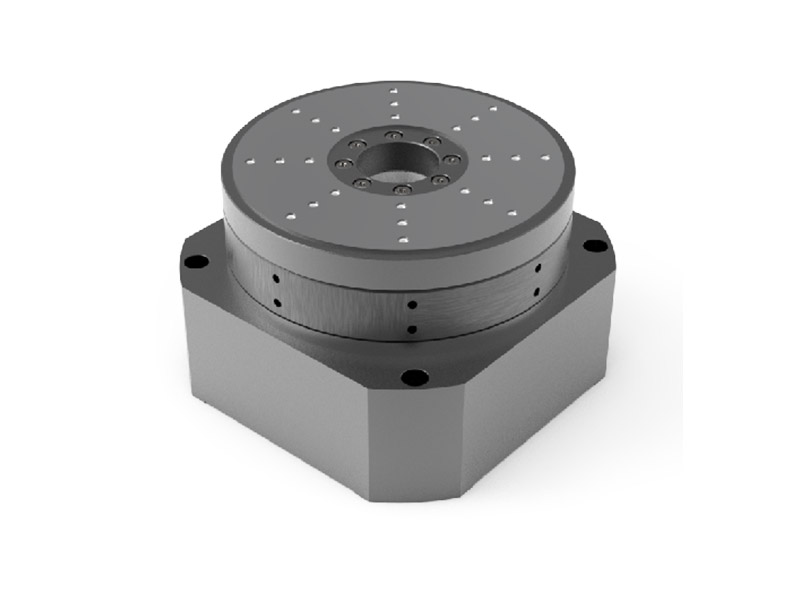

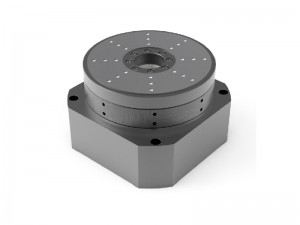

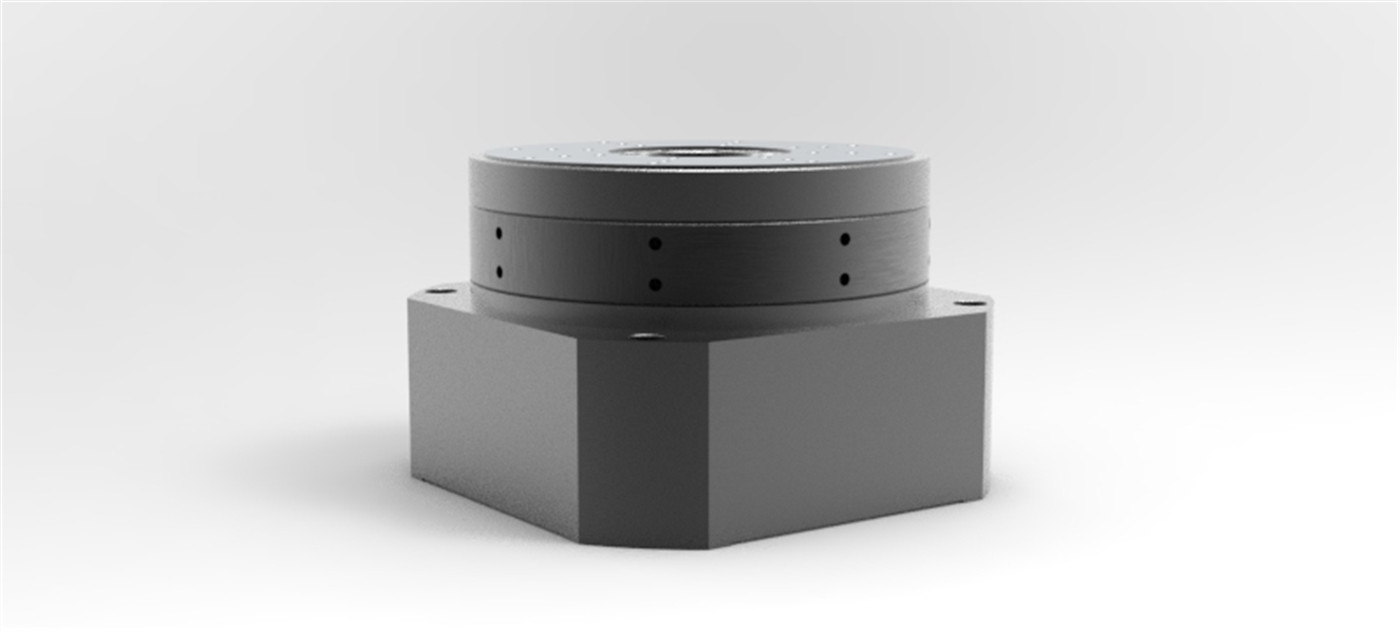

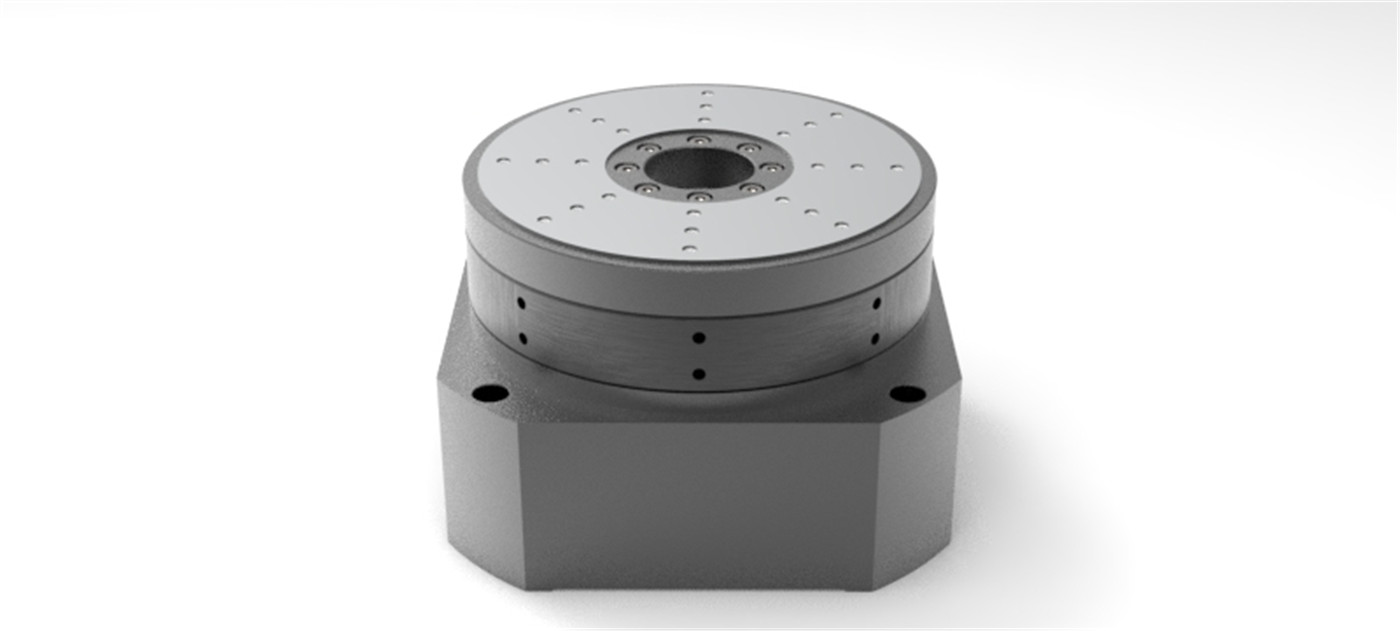

E-ART160 Air bearing rotary stage Rotation Stage with Air Bearings

Product Overview

Delivers best-in-class rotational motion, helping you to optimize your high-precision process Minimizes axial-, radial-, and tilt-error motions, reducing the need for extensive post-processing of parts and measurement data

Offers excellent positioning performance and velocity stability with high-resolution feedback Features a novel, non-influencing motor design that contributes to ultra-precise motion performance Provides generous load-carrying capacity without compromising on motion quality Integrates easily into precision systems and machines due to compact, lightweight form factor, as well as horizontal and vertical mounting and load-carrying capabilities

The E-ART160 of motorized rotation stages are designed for accuracy, precision, high stiffness, and ease of use, and can be mounted in any orientation.

Various options can be combined to create a solution ideal for point-to-point indexing or constant velocity scanning.

The E-ART160 stages offer superior travel accuracy, flatness, and wobble performance. Because they are friction free and require no maintenance or lubrication, they are ideal for use in cleanrooms.

● torque motor

● Brushless

● Slotless

● Low cogging torque

● Accessories and options

● Analog and digital position feedback Absolute encoder (optional)

● Absolute encoders supply explicit position information that enables immediate determination of the position.

● Therefore, no referencing is necessary when switching on and this increases efficiency and safety during operation.

Encoder

● Optional tip/tilt platform

● Custom mounting flanges

● PIglide filter and air preparation kits

● Single or multi-axis motion controllers and servo drives

● Base plates made of granite and systems for reducing vibration

Application fields

Optical alignment, metrology, inspection systems, calibration, scanning.

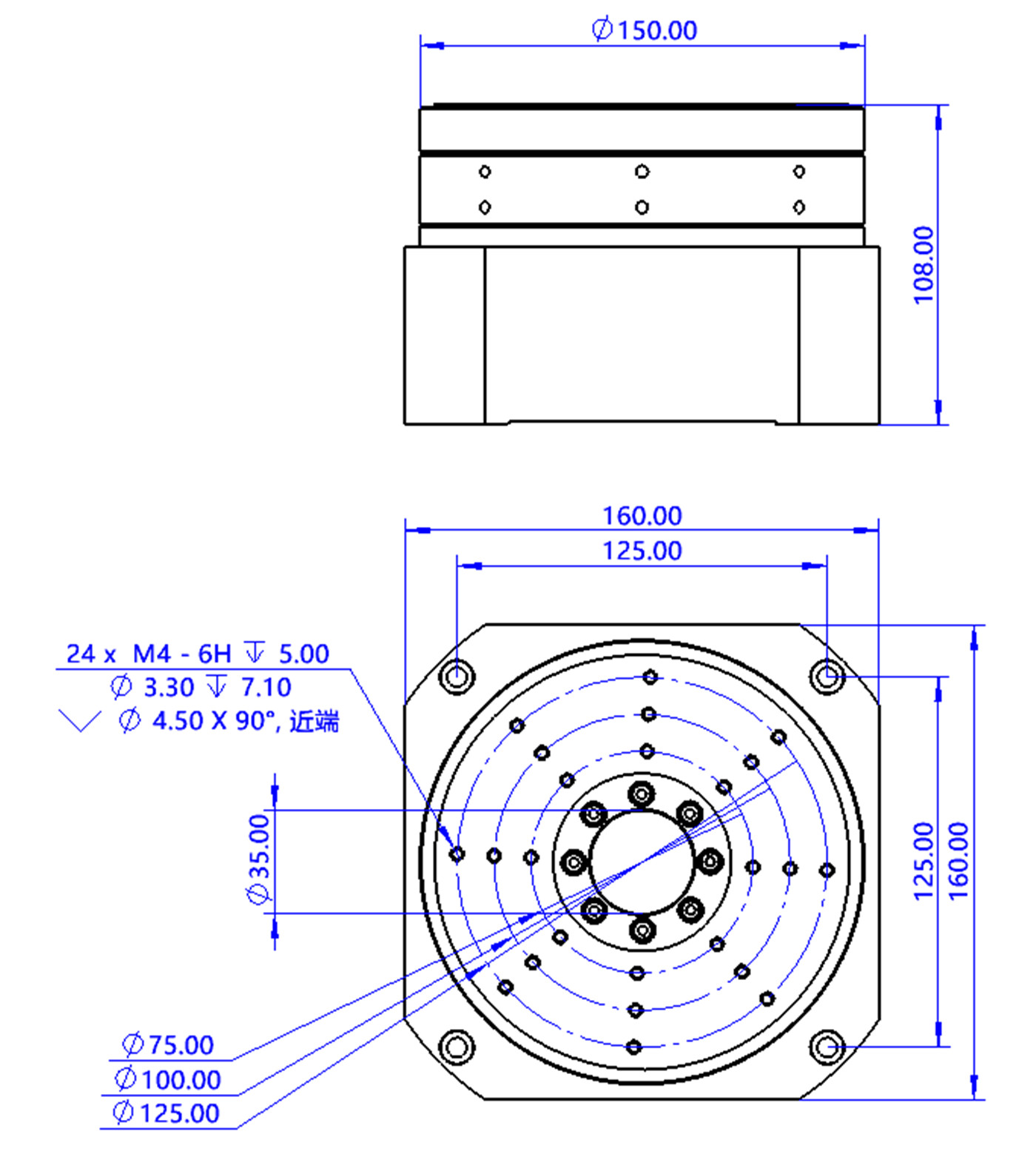

| Specification | Parameter |

| Motor torque | 1.7Nm rated 3.5Nm peak |

| Maximum revolution | 200rpm |

| Encoder | 11840line |

| Encoder resolution | 0.55sec(The digital quantity corresponds to 0.1um, and a higher resolution of 1Vpp is optional) |

| Repeatability Accuracy | ≤±1sec |

| Axial max loadcapacity(5bar) | 650N |

| Radial max loadcapacity(5bar) | 246N |

| Axial max stiffness(5bar) | 240N/um |

| Radial max stiffness(5bar) | 82N/um |

| Axial max bounce | <100nm |

| Radial max bounce | <100nm |

| Air consumption | 20NL/min |

1) What is the MOQ?

A: MOQ is 1 pcs.

Sample is available for customer to check the quality before bulk order.

2) Does your product ship overseas?

A: Yes, we ship our products internationally and have distributors in designated areas.

3) How do I ask for a quote on a specific product?

A:You can send a email to us , we will make a official quotation to you.

4) Are the products customizable?

A: We provide the ultimate engineered motion solutions for our clients. In many cases this involves customizing or configuring our standard products to a client’s unique application and specifications. Please contact us if you’re interested in customizing or configuring one of our standard products, or if you’d like to work with our engineering team to design a unique solution to meet your needs of the feedback source. If this velocity is exceeded, the commutation initialization is no longer valid, and commutation must be reinitizlized.